Dust collection system for brick kilns – timber workshop

Dust collection system for brick kilns – timber workshop

Producer:

Capacity: 7.5 – 300 kW

Voltage: 380V

Flow: 1,000 – 250,000 m3 / h

Pressure: 130 – 10,000 Pa

Categories: Industrial air filtration system, Equipment Industrial

Tags: hệ thống cấp khí sach than hoạt tính, hệ thống cấp khí tươi, hệ thống cấp khí tươi là gì ?, hệ thống hút bụi gỗ, hệ thống hút bụi kim loại hệ thống làm thoáng không khí nhà xưởng, hệ thống hút bui nhà xưởng, hệ thống hút khí công nghiệp, hệ thống lọc khí thải công nghiệp, hệ thống lọc không khí cao ốc, hệ thống lọc không khí dân dụng, hệ thống lọc không khí nhà ở, khử khuẩn lọc khí, lọc bụi công nghiệp, lọc bụi khử khuẩn ion, lọc bụi lò đốt, lọc bụi nhà máy may, lọc bụi vải, lọc bụi xí nghiệp, lọc bụi xưởng thép, lọc bụi xưởng đúc, lọc khí bảo vệ môi trường, lọc khí phân xưởng, lọc khí đốt than, màn lọc giá tốt, màn lọc khí 3 lớp, màn lọc khí thải, màn lọc than hoạt tính

- 0911.77.08.78 - 0907.526.268

- sales.247dichvu@gmail.com

- sales.247dichvu@gmail.com

Description

Dust collection system for brick kilns – timber workshop

Producer:

Capacity: 7.5 – 300 kW

Voltage: 380V

Flow: 1,000 – 250,000 m3 / h

Pressure: 130 – 10,000 Pa

Metal dust treatment system, Smoke exhaust treatment system, Soldering smoke treatment system, Paint exhaust system, Paint exhaust system, Activated charcoal deodorizing system, Activated carbon deodorizing system , Wood vacuum cleaner system, Wood vacuum cleaner system

PRODUCT INFORMATION

Installing dust collection systems in brick factories, especially ceramic tiles, is extremely necessary for brick factories, because it not only meets the regulations on environmental emissions, but also moreover, to ensure working environment, health protection for workers and workers …

Smoke and dust during the production of ceramic tiles mainly arise from the following production processes:

– Transporting raw materials from containers to mills.

– Cutting, molding process

– Surface polishing process.

– Brick burning stage

Dust research report in ceramic tiles manufacturing industry:

PRINCIPLES OF OPERATION

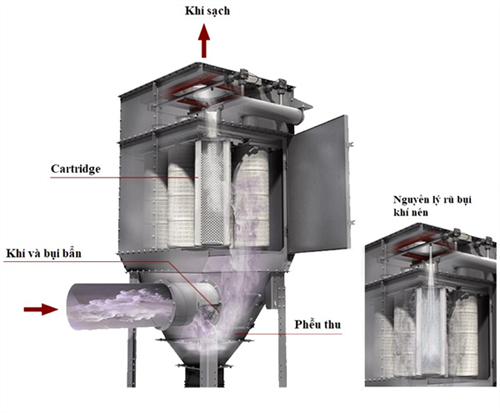

The gas and dust flows are charged to the top of the system suction points by the suction of centrifugal fans. Through the pipeline, these air lines will be sent to the dust filter chamber, where the speed of the air flow will drop dramatically so most of the dust particles lose their kinetic energy and fall directly into the funnel. The air and residual dust enter each separate chamber containing the cloth filter bag.

Here, dust is trapped on the outer surface of the filter bag, only clean air is passed through and escaped out. After a period of time the layer of dust will thicken to increase the resistance of the filter, this time the dust is removed by the pressure of compressed air shot inside the filter bag. During the cleaning process, dust falls into the hopper and is transported to the bottom of the dust filtration system.

VIETNAMESE FEATURES

– DUST EFFICIENCY ~ 98% for coarse dust (dust particle diameter ≥ 1µm)

– Replace bags quickly, simply and safely.

– Continuous operation.

– Automatic cleaning by pneumatic system without shutting down or stopping operation.

– The dust collector is an economical option as it requires minimal maintenance: only need to replace the filter bag periodically.

More :